Namiki | Coreless Motors

Namiki | Coreless Motors

-

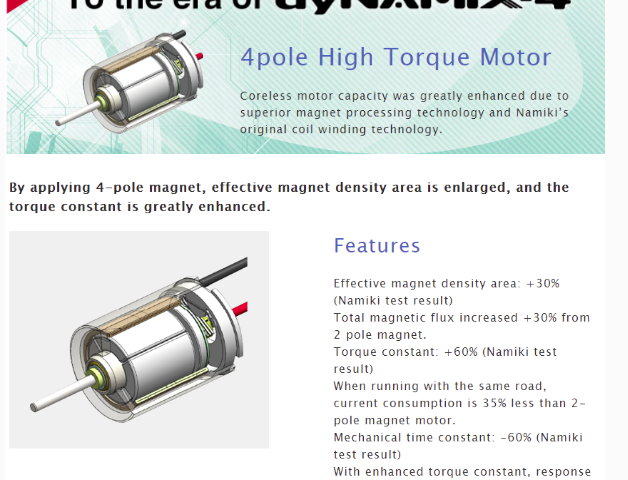

As a pioneer in coreless motors, Namiki has pursued development of high torque motors. Generating high torque by enlarging the magnet or inputting a large current has its limitations in terms of heat generation and magnet materials. Namiki tried to increase torque by increasing number of magnet poles form 2 to 4.

-

By applying a 4-pole magnet, the effective magnet density area is enlarged. As a result, it contributed to a higher torque constant and low current consumption. Moreover, it enhanced mechanical time constant, so even the response speed became quicker.

-

Using diamond processing technology, a 4-pole magnet processing method has been established in Namiki.

More About Motor Units:

Motor assemblies require a wide range of technical elements such as precision drive, high output, light weight, less heat generation, less vibration, and low current consumption.

Adamant Namiki combines its actuation technology including motor, gearbox, non-energized locking system “dyNALOX” micro clutch, torque transmission mechanism and motion control with its precisely processed parts and assembling skill using the company’s core “cutting, grinding and polishing” technology to provide unique and optimized solutions.

For more information on on Namiki, contact the Applied Motion Solutions sales engineering team.